Adhesive anchors require a different strength calculation compared to normal bolts, as their strength needs to be determined based on three factors: concrete strength, adhesion strength between concrete and resin, and anchor (screw) strength.

The “Chemical Anchor” is a registered trademark of NIHON Decolux Co., Ltd. and is the first adhesive anchor manufactured and sold domestically in Japan. I will explain their calculation method, along with my own design and installation experience at NIHON DECOLUX Co., Ltd.

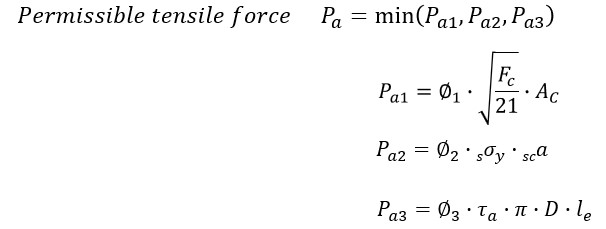

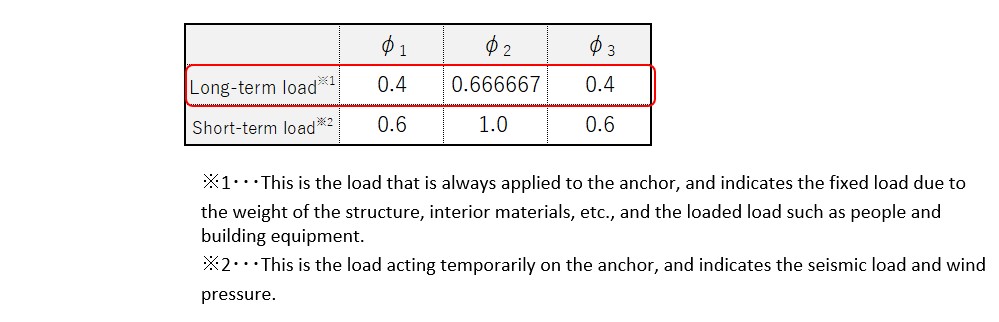

Three points of strength to be confirmed

- Pa1:Permissible tensile force (N) per one chemical anchor, determined by the cone-shaped failure of the settled concrete body.

- Pa2:Permissible tensile force (N) per one chemical anchor, determined by the yield of the anchor reinforcing steel material.

- Pa3:Permissible tensile force (N) per one chemical anchor, determined by the adhesion strength of the resin to the concrete.

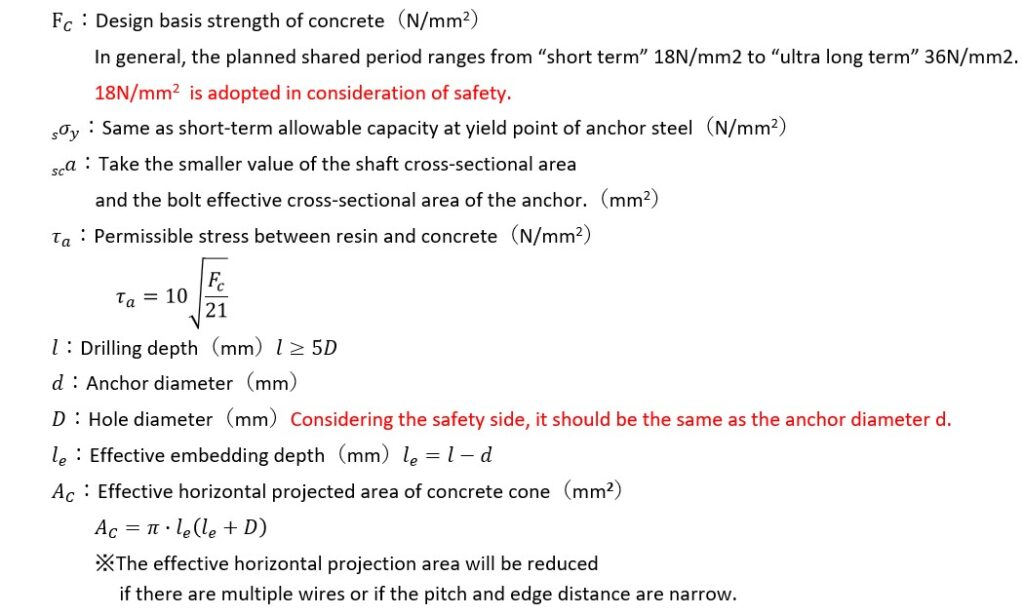

Symbol

I have listed below the symbols used in the above calculation formula and their meanings. Based on my past experience, I have written comments in red for the actual values to be used.

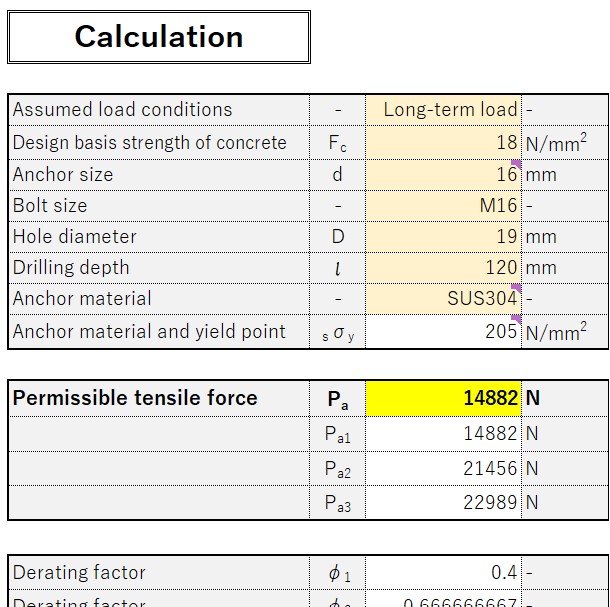

How to use “Calculation sheet”

Actual calculation examples are omitted, and you can confirm the calculations by downloading an Excel file with the formulas included. There are only four input fields to fill out. The same Excel file also includes sheets with calculation formulas from other manufacturers as well as calculation sheets for metal expansion anchors.

Click to go to the download page

The separate sheets of the Excel file also include calculation sheets from other manufacturers as well as strength calculation sheets for metal expansion anchors.

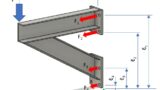

Once the permissible tensile force has been calculated, it is necessary to calculate the load on one anchor from the load on the bracket of a cantilever beam fixed with a chemical anchor. If the load on one anchor is smaller than the permissible tensile force, there is no problem. The calculation method for the load on one anchor that fixes the bracket can be found in the following article for reference.

We have introduced the comparison of calculation formulas by manufacturer in the following article.

Recommended Adhesive anchors

If you need to fix equipment with 10 or more anchor bolts, we recommend the injection type “EL350” cartridge for chemical anchors from NIHON DECOLUX Co., Ltd. It is efficient in injecting the anchor hole, cost-effective, and ensures reliable construction. When using this product, you also need to use the ELGガン“>ELG gun. The company’s website has a clear explanation with a video on how to use (construction method).

ISO and JIS for material name

JIS (Japanese Industrial Standards) are national standards used in Japan, while ISO (International Organization for Standardization) are international standards used worldwide. ISO standards cover a wide range of topics, including materials, but ISO does not have direct equivalents to JIS material grades.

However, some JIS material grades are roughly equivalent to ISO material grades, and it is possible to find correspondences or conversions between them. For example:

・SS400: ISO 630-2 S275JR (EN 10025-2 S275JR)

・SUS304: ISO 3506-1 A2 (EN 10088-3 X5CrNi18-10)

・SD295A: No direct equivalent in ISO. It may be similar to ISO 630-3 S355NL (EN 10025-3 S355NL) or ISO 6935-2 Grade F (EN 10067 Grade A)

・SNR490B: ISO 630-3 S420NC (EN 10149-3 S420NC)

・SD345: No direct equivalent in ISO. It may be similar to ISO 630-3 S355NL (EN 10025-3 S355NL) or ISO 6935-2 Grade F (EN 10067 Grade A)

Note that these equivalences are not always exact and should be used as a reference only. It is always important to consult the specific material standards and specifications for accurate and reliable information.

コメント